In 1918, at the end of the Great War, Fiat introduced its first agricultural tractor, the “702,” which went into production in 1919 at the Corso Dante plants in the Savoy city. This marked the beginning of an adventure that led the company to become, for some time, the leading European producer and also one of the top global producers. The “702” was powered by a side-valve four-cylinder engine with a displacement of 6,235 cc, running on kerosene, and producing 30 horsepower at 900 rpm. Robust and reliable, as well as of considerable size, it weighed about 2,800 kg and was produced for two years in 1,100 units, a significant number but far from the thousands of units of the Fordson “F.” From 1920, the “702 A,” “702 B,” “702 Bn,” “703 B,” and “703 Bn” were released in succession, all machines that allowed Fiat to establish itself in the Italian market but faced competition from global giants, mostly American, who had more compact, lighter, and cheaper machines.

The Start of the ‘700 Project in 1925

For this reason, in 1925, the company designed a smaller and lighter tractor, the “700,” boasting 28 horsepower and weighing 1,900 kg. It was assembled as a prototype in Turin but later entered series production in Modena. Fiat wanted a plant dedicated expressly to tractors and, in 1927, with the approval of the Ministries of War and Finance, acquired a large plant in Modena. Originally built by Officine Reggiane at the beginning of the century to repair and assemble railway materials, it was repurposed during the Great War for the construction of shells and military material, then remained unused and was available for Fiat.

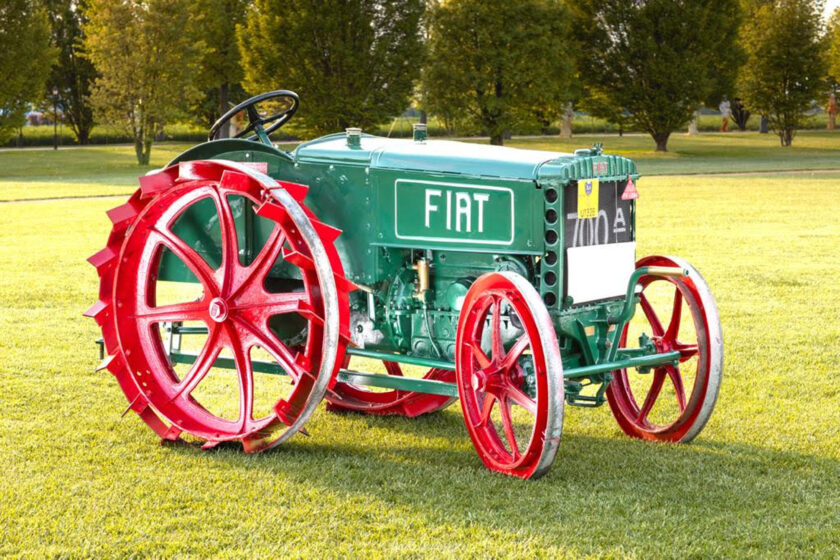

At the beginning of 1928, Fiat renamed the complex “Oci,” “Officine Costruzioni Industriali,” and began producing the “700,” adding the suffix “A” to distinguish the Modena-made models from those previously made in Turin. This was a smart choice as the people of Modena combined a passion for mechanics with knowledge of agricultural issues. The “700 A” was equipped with a four-cylinder overhead valve engine with a displacement of 3.5 liters, producing 30 horsepower at the flywheel and 28 at the pulley at a nominal speed of 1,500 rpm. Compared to its predecessors, it had a better power-to-weight ratio, at 63 kg per horsepower, was more agile, lighter, and versatile.

Two Tanks for Diesel and Gasoline

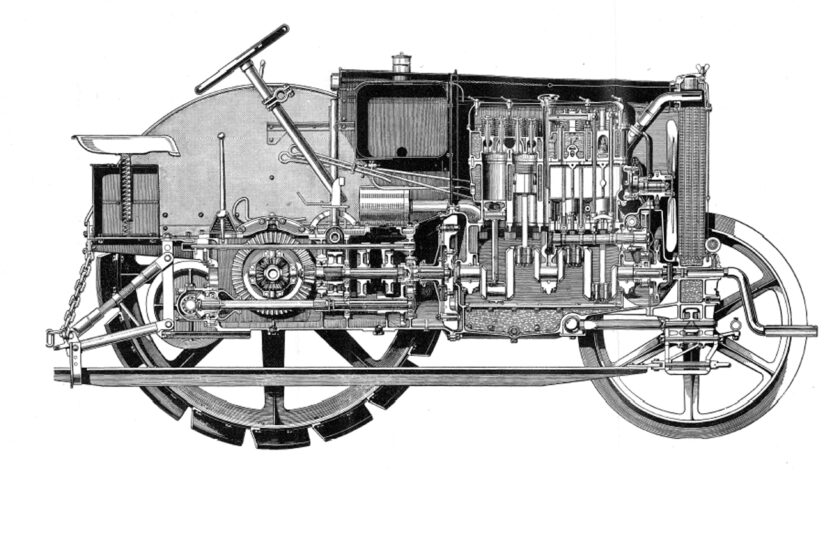

The engine was started with a crank using gasoline, while it ran on diesel or kerosene when hot, thanks to an atomizer that allowed for a seamless switch between fuels. For this purpose, it had two tanks with separate filling nozzles in front of the dashboard. The right tank was for diesel or kerosene and held 50 liters, while the left tank was for gasoline with a capacity of eight liters.

Once the engine was started on gasoline through a series of not-so-quick operations, it was left running for five or six minutes to bring the cooling water temperature to around 100 degrees before switching to diesel. Without a thermometer, the water temperature was checked by observing steam coming from a dedicated hole in the radiator nozzle, and to facilitate warming in cold climates, a curtain on the radiator could be operated by a chain from the driver’s seat. The ignition was provided by a high-tension magneto driven by the same shaft as the water pump, and the magneto activated the four spark plugs mounted at a 45-degree angle to the combustion chambers. Lubrication was managed by a pump controllable via a pressure gauge on the dashboard, the only instrument installed. In the early versions, the engine oil level was also visible through a vertical glass tube, later replaced by a more conventional dipstick.

Average Fuel Consumption for the Category

The declared hourly fuel consumption was over six kilograms of diesel, not very low but adequate for the horsepower produced. The clutch was operated by a pedal on the right side of the steering column and could be inspected and adjusted through a cover on the top of the transmission case. The transmission operated in a bath of castor oil, from the gearbox to the final drive. The gearbox offered three forward speeds and one reverse, allowing a top speed of 11 kilometers per hour in direct drive. Clearly, the first two gears were for work, while the third was for transport and transfers. This created a “gap” between the second and third gears, so for those who did not continuously perform heavy work, a gearbox with faster first two gears was available. Gear engagement was easy and smooth, and the lack of synchronizers was not missed, while the brakes were a major weak point, consisting of a pulley inside the gearbox operated by a hand lever on the left side of the driver’s seat.

This system could be locked in place using a toothed sector and also functioned as a parking brake, but its action left much to be desired, unlike the steering, which acted on a pair of helical gears. It was highly geared and therefore easy and light to operate, acting on an oscillating axle that supported monolithic soft steel wheels, with the front wheels equipped with “L” rims that penetrated the ground to maintain direction.

The rear wheels had diagonal tread blades that could be removed when not needed, reducing the width of the “700 A” from 160 to 138 centimeters. Noteworthy was the “T” drawbar anchored to the front axle, providing greater stability even in heavy work. Overall, the machine was very modern for its time but faced a dark period marked by crises, wars, conflicts, and destruction, which ended only when it was replaced by the “600” model.

Fiat “700”, Sciancata” and “Stradale” Versions

For those frequently plowing furrows, a modification of the “700 A” allowed the right axles to be extended by 30 centimeters, placing the center of gravity midway between the two wheels and providing greater traction with less slippage. This could be ordered directly from the factory and was known as the “sciancata” model. The driver’s seat was well-protected by the rear wheels, spacious, allowing easy access to all controls, and featured a seat suspended on a spring. The dashboard was spartan, with the ground button on the left, the chain for adjusting the radiator curtain height in the center, and the engine oil pressure gauge on the right. The “700 A” was also available in a road version with ballasted wheels and solid rubber tread. This setup included acetylene headlights, fenders for the front wheels, a specific silencer, and an additional brake on the rear wheels. This version reached a top speed of 14 kilometers per hour and could tow trailers up to 38 tons.

From Fiat “700 A” to Fiat “700 D”

The Fiat “700 A” is rightfully one of the tractors that made history and was produced in 1,943 units. However, in 1931, it was replaced by the “700 B,” available in “Bm” and “B1” military variants, “Bv” fast, and “Bvv” very fast. Produced until 1942 in 1,565 units, it differed little from its predecessor. The shape of the hood/tank was different, the front wheels had seven spokes, and three different gear ratios were available. Heavier than the “700 A” with a consequent increase in traction capacity, the “700 B” was replaced in 1942 by the “700 D,” identical to the “B” but with the engine displacement increased to 3,950 cc thanks to a bore increase from 90 to 95 millimeters. It gained a few more horsepower and was marketed until 1950, when its successor, the “600” model, was already in production.

It should be noted that the transition from model “B” to model “D” was induced by the fact that the suffix “C” in Fiat was reserved for crawler tractors. The “700” also gave rise to a similar version in 1932, becoming one of the first tracked tractors built in Italy, but that is another story to be told another time. Over twenty-five years, a total of 4,561 “700” units on wheels were produced, a considerable volume given the period in question, marked by wars, destruction, and crises.

Title: Fiat “700”, on the scene for a quarter of a century

Author: Massimo Misley

Translation with ChatGPT